Prototype Manufacturing Services

Prototype Manufacturing Services

Eliminate risk, execute design sprints, and accelerate your path to volume production.

Prototype Manufacturing Services

Eliminate risk, execute design sprints, and accelerate your path to volume production.

What type of prototype do you need?

Build the right type of prototype to match your project requirements.

What type of prototype do you need?

Build the right type of prototype to match your project requirements.

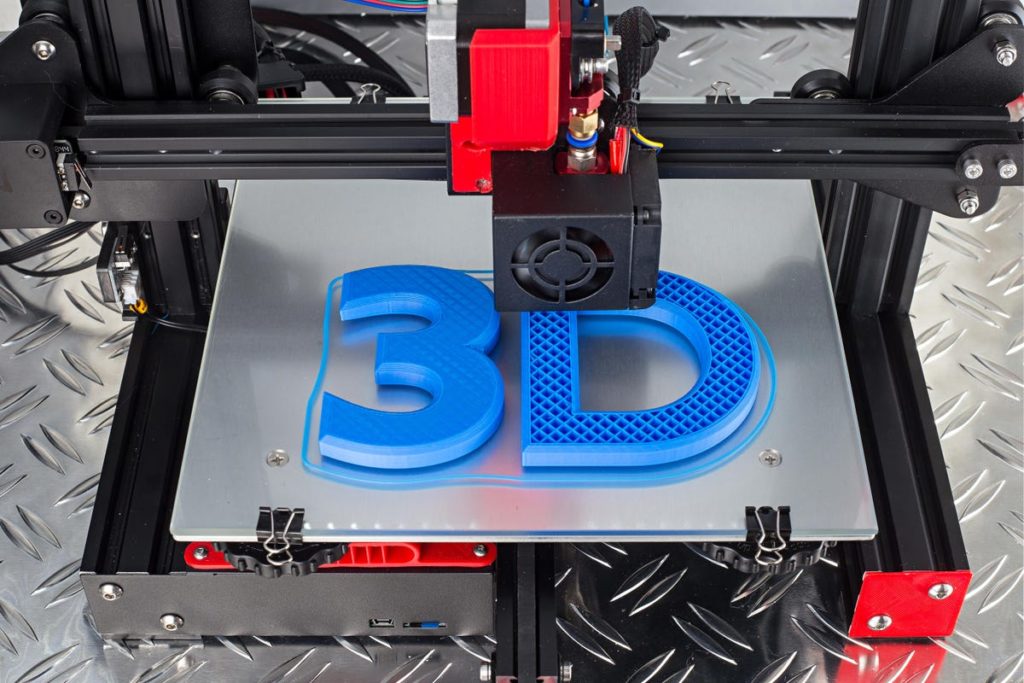

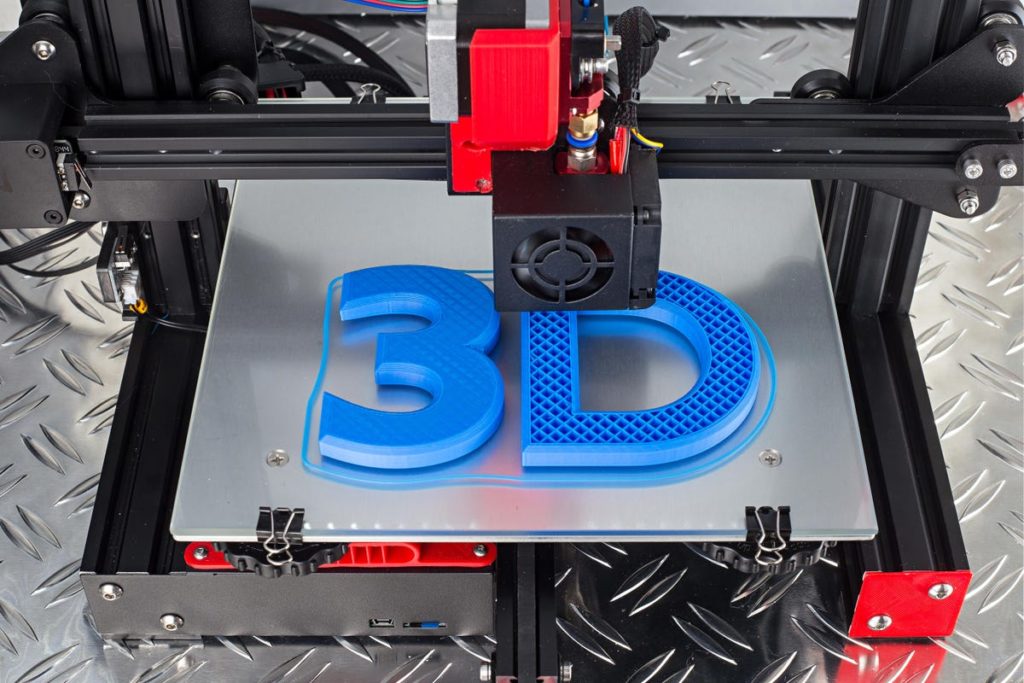

Rapid Prototypes.

Our in-house rapid prototype shop is outfitted with 3D-Printing, SLA, and CNC machines, enabling for rapid prototyping. Throughout the product development process, we frequently prototype parts and components to evaluate their fit, form, and function. The prototype technique we employ is determined by the part's quality, time, and functional requirements.

Rapid Prototypes.

Our in-house rapid prototype shop is outfitted with 3D-Printing, SLA, and CNC machines, enabling for rapid prototyping.

Throughout the product development process, we frequently prototype parts and components to evaluate their fit, form, and function. The prototype technique we employ is determined by the part’s quality, time, and functional requirements.

Interactive MVP Prototypes.

Building a minimum-viable-product (MVP) prototype allows you to evaluate the user experience early on in product development. Our design and engineering team devises inventive prototyping methods for your interactive product concept early in development. This enables you to quickly receive user feedback and refine the functionality, saving you time and money on development throughout the project.

Interactive MVP Prototypes.

Building a minimum-viable-product (MVP) prototype allows you to evaluate the user experience early on in product development.

Our design and engineering team devises inventive prototyping methods for your interactive product concept early in development. This enables you to quickly receive user feedback and refine the functionality, saving you time and money on development throughout the project.

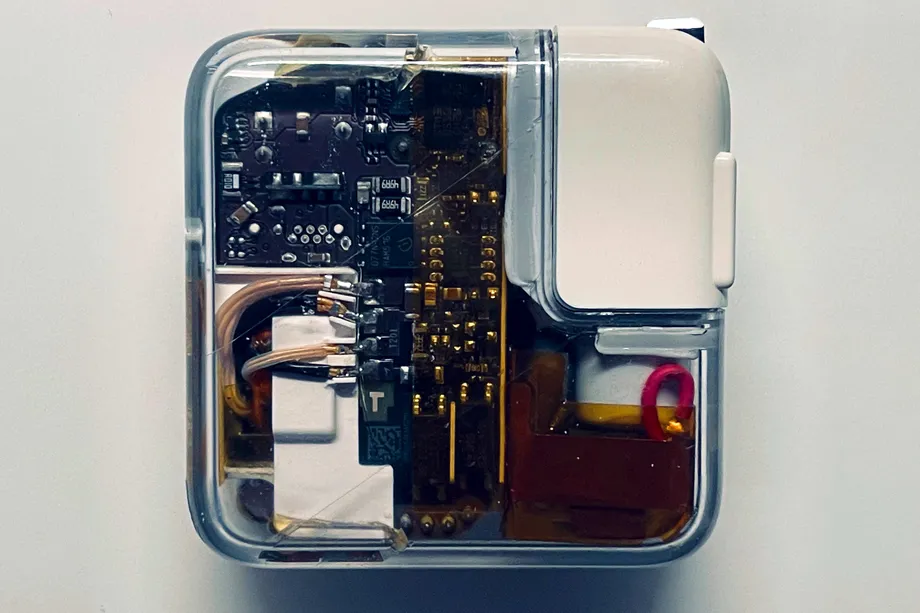

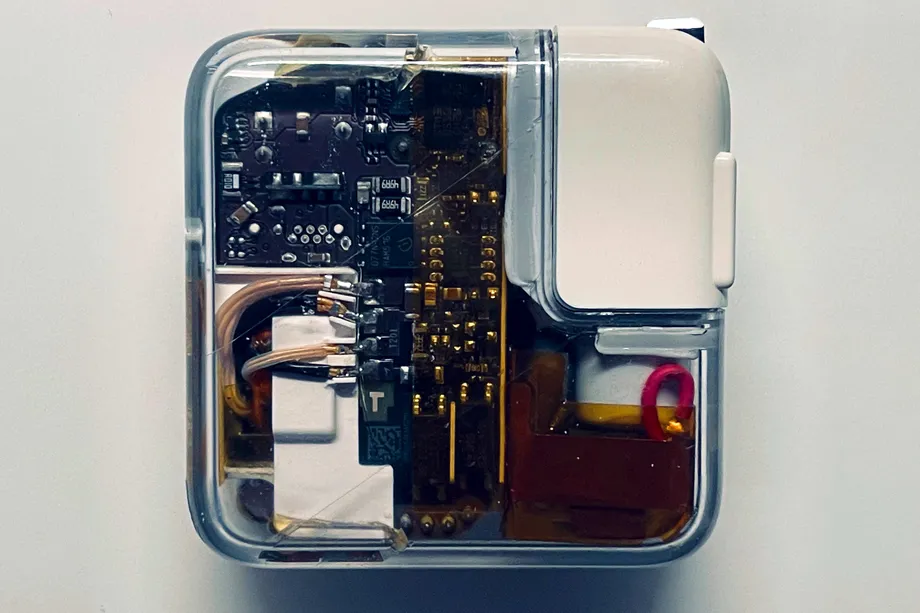

Electronics Prototypes.

Before diving into custom Printed Circuit Board (PCB) design, de-risk your project by beginning with breadboards and off-the-shelf (OTS) electronics. Utilizing OTS components and development boards early on in the design process enables a rapid transition from concept to tangible product for user testing. After defining essential features and functionality, we help you determine whether a custom or off-the-shelf (OTS) component is best for your product and business objectives.

Electronics Prototypes.

Before diving into custom Printed Circuit Board (PCB) design, de-risk your project by beginning with breadboards and off-the-shelf (OTS) electronics.

Utilizing OTS components and development boards early on in the design process enables a rapid transition from concept to tangible product for user testing. After defining essential features and functionality, we help you determine whether a custom or off-the-shelf (OTS) component is best for your product and business objectives.

To reduce product development risk and accelerate time to market, numerous engineering designs rely on extant solutions.

To reduce product development risk and accelerate time to market, numerous engineering designs rely on extant solutions.

Reverse engineering complex products.

Using existing, non-proprietary solutions during product development is made possible by reverse engineering existing products and gathering a vast array of information pertinent to particular design challenges. This is especially essential for complex mechanisms and technical products.

Reverse engineering complex products.

Using existing, non-proprietary solutions during product development is made possible by reverse engineering existing products and gathering a vast array of information pertinent to particular design challenges. This is especially essential for complex mechanisms and technical products.

Hypothesis Testing.

Your product vision may depend on one or two unproven hypotheses. Utilizing virtual simulation and physical prototyping, test these beforehand.

Engineering and user testing of your design concepts early on can eliminate significant design, function, and cost issues. This expedites your time to market by providing a user-verified solution without any surprises.

Hypothesis Testing.

Your product vision may depend on one or two unproven hypotheses. Utilizing virtual simulation and physical prototyping, test these beforehand.

Engineering and user testing of your design concepts early on can eliminate significant design, function, and cost issues. This expedites your time to market by providing a user-verified solution without any surprises.

Product/Market Fit

With a Minimum Viable Product (MVP) prototype, you can determine the correct product/market fit and put your product on the path to success. For testing and refining a physical product concept, the construction of a Minimum Viable Product (MVP) prototype is essential for hardware. Our hardware MVP prototypes range from production-quality models for tradeshows to rudimentary, low-fidelity prototypes for rapid evaluation and usability testing.

Product/Market Fit

With a Minimum Viable Product (MVP) prototype, you can determine the correct product/market fit and put your product on the path to success.

For testing and refining a physical product concept, the construction of a Minimum Viable Product (MVP) prototype is essential for hardware. Our hardware MVP prototypes range from production-quality models for tradeshows to rudimentary, low-fidelity prototypes for rapid evaluation and usability testing.

Moving to Production.

Want to jump directly into mass production? First, ensure that your alpha production intent prototype is accurate.

Alpha prototypes are the final opportunity to make modifications to a physical product prior to mass production. We create alpha prototypes that replicate your volume manufacturing process and allow engineers, regulators, and end users to evaluate the quality and functionality of your product with precision.

Moving to Production.

Want to jump directly into mass production? First, ensure that your alpha production intent prototype is accurate.

Alpha prototypes are the final opportunity to make modifications to a physical product prior to mass production. We create alpha prototypes that replicate your volume manufacturing process and allow engineers, regulators, and end users to evaluate the quality and functionality of your product with precision.

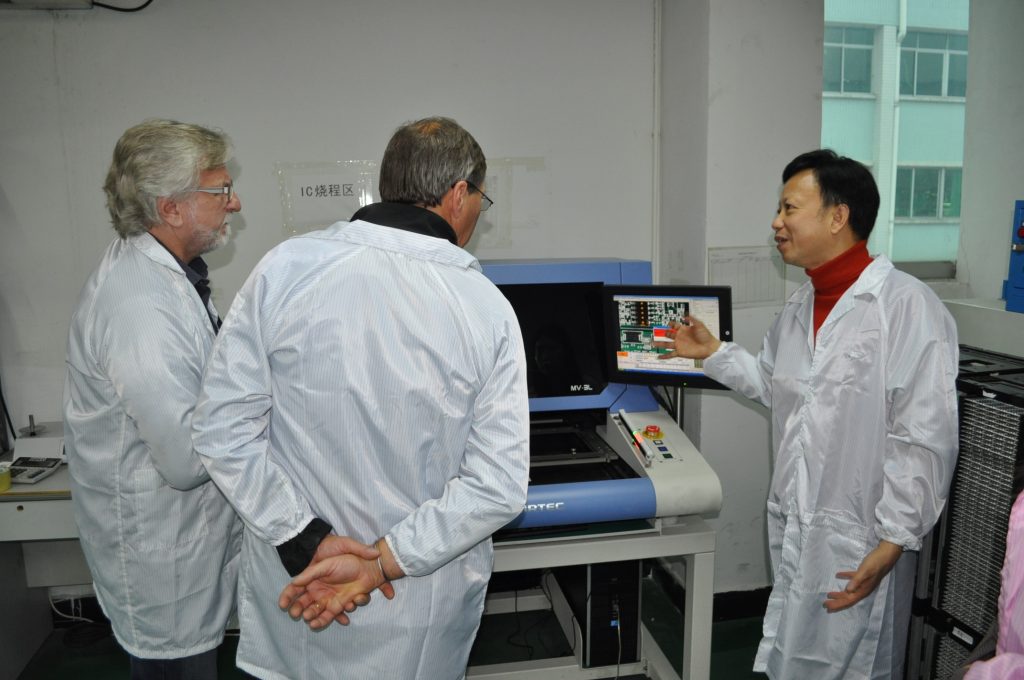

PROTOTYPING EXAMPLES

Many techniques and materials for prototyping are sourced from reputable global prototyping specialists.

Prototyping during the product development process.

At each stage of product development, we create various types of prototypes to quantify risk.

Prototyping during concept design is rapid process where the goal is to determine the optimal product concept solution.

Types of prototypes we build during concept design include:

- 3D CAD product concepts – high resolution renderings

- Hand sketches and 3D CAD geometry for strong communication of concept options

- Low fidelity mock-up non-working prototype for user reaction evaluations

- Scale model mock-ups: to evaluate Ergonomics, Cognitive and Appearance model reactions by users

- Experiential UI concept simulations, storyboarding, wireframes to assess ease of use (keys, displays, audio interfaces)

- Works-like off the shelf customized breadboard electronics to evaluate function, establish specifications

- Fast code software/firmware of near off the shelf components to demo function, fine tune positive reactions to early stage prototypes

- Finite Element Analysis (Thermal, Fluids, Stress, Audio…) to determine feasible structural and geometric configurations

- Modified Off-the-shelf components customized and library software modules customized for testing features and verifying hypotheses

- Interactive Wizard of Oz prototypes that use off the shelf customized components to assess high value attributes of product

During the Detailed Engineering stage prototyping is used to de-risk your product concept solution.

Types of prototypes built during this stage may include:

- Bench model breadboard electronics to optimize sub-system product features operation and specifications

- Works-like functional prototypes for mechanism modeling of features for refinement and performance evaluation

- Quick cut in-house machined parts and in-house additive rapid prototype mock-up modeling to test and refine the design

During the Pre-Production Prototyping stage, the goal is to create a high-fidelity production intent prototype to verify the design.

Types of non-production intent prototypes we create during this stage include:

- High fidelity production intent ‘alpha’ physical prototype (machined, molded, stamped, formed, SLA, SLS… additive process parts created)

- Fully functional additional ‘alpha’ prototypes created for debug confirmation and verification

- Fully functional working ‘alpha’ prototype – integrated electronic hardware+software features and function debug confirmation and verification

- Low volume custom PCB’s to assist in design verification process

- Quick prototype material mold to produce low volume hard to prototype parts such as rubber components, fabrics, cabling, special materials

- Regulatory approval testing and performance testing is possible with prototype product

- Prototype product is available for comment from users, buyers and for collateral such as product photography

During the Manufacturing support stage, final production prototypes are built to verify design transfer to production.

Types of production prototypes built by manufacturing partners may include:

- Off tool production parts to measure parts, approve part tolerances and approve tools

- Fully product assemblies for pilot run product builds and design approval of all product specifications

- Pre-release product available for external regulatory testing submission and approval

- Pre-release product and parts for materials testing and approval

- Pre-release product is available for user, customer and market approval

Prototyping during the product development process.

At each stage of product development, we create various types of prototypes to quantify risk.

Prototyping during concept design is rapid process where the goal is to determine the optimal product concept solution.

Types of prototypes we build during concept design include:

- 3D CAD product concepts – high resolution renderings

- Hand sketches and 3D CAD geometry for strong communication of concept options

- Low fidelity mock-up non-working prototype for user reaction evaluations

- Scale model mock-ups: to evaluate Ergonomics, Cognitive and Appearance model reactions by users

- Experiential UI concept simulations, storyboarding, wireframes to assess ease of use (keys, displays, audio interfaces)

- Works-like off the shelf customized breadboard electronics to evaluate function, establish specifications

- Fast code software/firmware of near off the shelf components to demo function, fine tune positive reactions to early stage prototypes

- Finite Element Analysis (Thermal, Fluids, Stress, Audio…) to determine feasible structural and geometric configurations

- Modified Off-the-shelf components customized and library software modules customized for testing features and verifying hypotheses

- Interactive Wizard of Oz prototypes that use off the shelf customized components to assess high value attributes of product

During the Detailed Engineering stage prototyping is used to de-risk your product concept solution.

Types of prototypes built during this stage may include:

- Bench model breadboard electronics to optimize sub-system product features operation and specifications

- Works-like functional prototypes for mechanism modeling of features for refinement and performance evaluation

- Quick cut in-house machined parts and in-house additive rapid prototype mock-up modeling to test and refine the design

During the Pre-Production Prototyping stage, the goal is to create a high-fidelity production intent prototype to verify the design.

Types of non-production intent prototypes we create during this stage include:

- High fidelity production intent ‘alpha’ physical prototype (machined, molded, stamped, formed, SLA, SLS… additive process parts created)

- Fully functional additional ‘alpha’ prototypes created for debug confirmation and verification

- Fully functional working ‘alpha’ prototype – integrated electronic hardware+software features and function debug confirmation and verification

- Low volume custom PCB’s to assist in design verification process

- Quick prototype material mold to produce low volume hard to prototype parts such as rubber components, fabrics, cabling, special materials

- Regulatory approval testing and performance testing is possible with prototype product

- Prototype product is available for comment from users, buyers and for collateral such as product photography

During the Manufacturing support stage, final production prototypes are built to verify design transfer to production.

Types of production prototypes built by manufacturing partners may include:

- Off tool production parts to measure parts, approve part tolerances and approve tools

- Fully product assemblies for pilot run product builds and design approval of all product specifications

- Pre-release product available for external regulatory testing submission and approval

- Pre-release product and parts for materials testing and approval

- Pre-release product is available for user, customer and market approval

How much do prototypes cost?

The 4 challenges of voice

ul design

prototyping an audio interface device with amazon alexa

How to design hardware products for new thread wireless protocol

How much do prototypes cost?

The 4 challenges of voice

ul design

prototyping an audio interface device with amazon alexa

How to design hardware products for new thread wireless protocol