What are EMI and EMC?

What are EMI and EMC?

Wireless communication is all around us in the world today. From key fobs to unlock your car. Bluetooth to connect to your earbuds or smart watch, WIFI for many devices, or even traditional AM/FM broadcasting, wireless radio transmission has become the norm. Plus, wireless charging is also gaining traction – not just for your phone, but now even for electric cars. These devices are all intentional transmitters of electromagnetic waves. All these signals exist in the same space at the same time. Making electromagnetic interference (EMI) and electromagnetic compatibility (EMC) two of the most important considerations in modern product development. The problem is not confined to wireless devices but applies to all devices with electronics. Can you name an electrical product that does not contain electronics today?

Types of EMI

Types of EMI

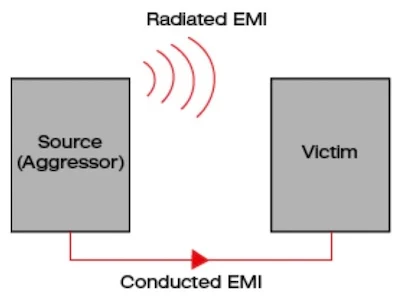

EMI is electromagnetic interference of a device by an unwanted disturbance. EMI is a byproduct of fast switching processes – whether a switching power supply or high-speed digital processing as in a computer. EMI can be either conducted or radiated, and it is important to understand both types.

Figure 1. Conducted and Radiated EMI

Figure 1. Conducted and Radiated EMI

Conducted EMI: Physical coupling from direct contact

Conducted EMI results from currents flowing through imbalances in circuits or through parasitic circuit elements of components or trace inductances and capacitances. The noise couples to other circuit parts either magnetically (inductive coupling) or electrically (capacitive coupling).

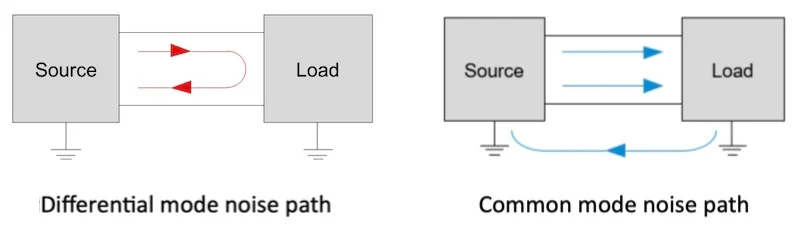

Currents are classified as differential if they flow opposite directions as in the source and return path or as common mode. If they flow in the same direction through both source and return path, then completing the circuit through a ground path.

Currents can either be classified as differential or common mode:

- Differential Currents: Flow opposite directions as in the source and return path

- Common Mode: Flow in the same direction through both source and return path, and then complete the circuit through a ground path

Even though the currents are extremely small, just microamperes in the presence of devices larger operating currents (amperes), they can easily be enough to cause a failure to meet EMC standards. Typically conducted noise is at lower frequencies, between 150 kHz to 30 MHz, because the components and traces are too small to form antennas.

Radiated EMI: Coupling over the air from antennas

Radiated EMI is caused when the current paths on the circuit board layout encompass large enough areas to form loop antennas or dipole from which signals radiate. Radiated noise is considered to be in the range of 30 MHz to 1 GHz. This is the upper limit of the standards, not the noise; many computers and the new 5G cellular networks operate well above this limit. Standards generally lag technological innovation.

Electromagnetic Compatibility

Electromagnetic Compatibility

EMC is twofold. First, the device must not transmit interference when functioning; when it creates EMI, the device is called the aggressor. Secondly, the device needs to protect itself from possible interference from other devices when they are operating normally so it will not be a victim of EMI. The device should operate properly in the real-world environment with other devices.

In addition to the high frequency interference, EMC also encompasses several types of transient immunity:

- Electrostatic Discharge (ESD) – These are high voltage, low power discharges that can happen either through the air or by direct contact. It’s the spark you get when reaching for the doorknob after walking across a carpet on dry winter day.

- Electrical Fast Transients – An example would be the arcs created when opening a switch. Breaking the current flow causes an arc, but, since switch contacts bounce, the interruption happens many times, creating a burst of electrical noise.

- Surge – This third type is often seen on mains powered devices as a result of a lightning strike. These are high voltages with high currents which can cause significant damage.

Meeting EMC Standards

Meeting EMC Standards

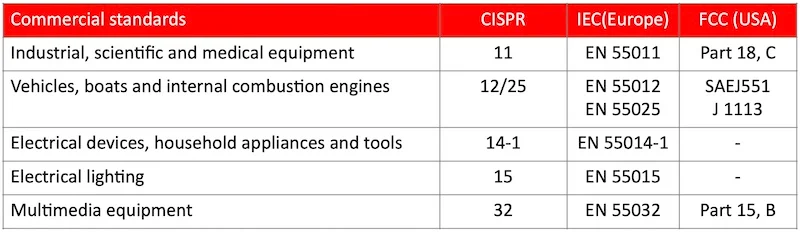

All commercial products must meet minimum performance requirements developed by standardization bodies like IEC (International Electrotechnical Commission). CISPR (International Special Committee on Radio Interference), FCC (Federal Communications Commission), and others which have been adopted into the laws of most countries. This makes it a legal requirement in order to sell devices.

Table 1. An example of some of the most common EMC standards

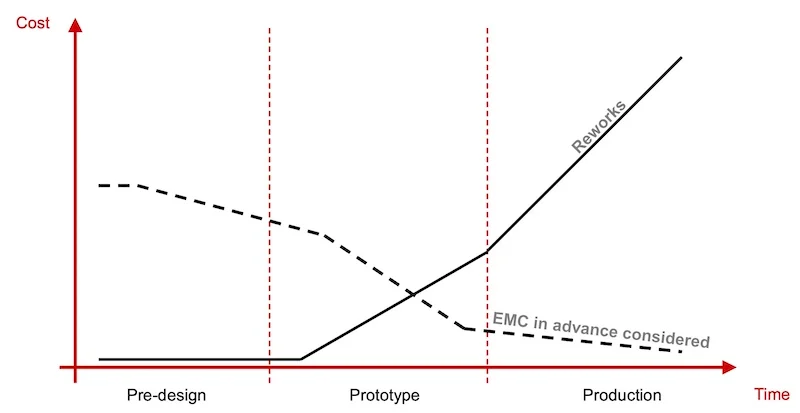

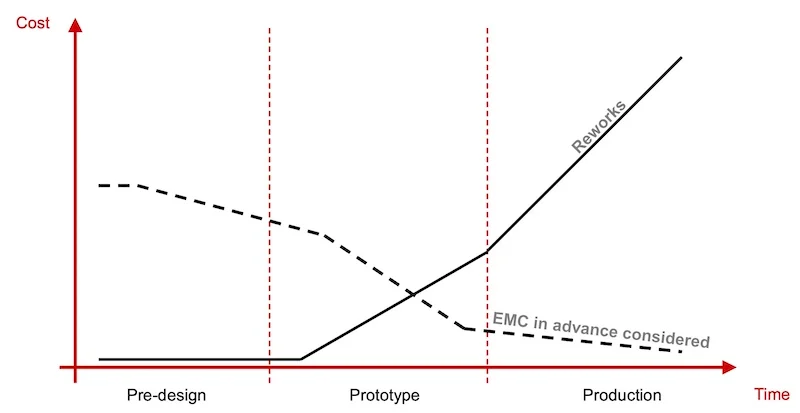

EMC is tested under strictly controlled conditions. Conducted emissions need defined ground planes and source impedances. While radiated emissions are done in labs equipped with anechoic chambers or even in open fields (OATS – Open Area Test Sites). This necessitates that EMC be considered early in the product development cycle. Failure to do so often results in costly rework, delayed product launches, and added expenses.

Figure 3. The cost of fixing any EMC problems increases as product development moves closer to production. Early consideration reduces development cost and time.

Components to Meet EMC Standards

Components to Meet EMC Standards

EMC is achieved first by careful layout and then by adding the correct components to the circuit which act as filters and absorbers of the unwanted signals. Some components that can play a part in attenuating unwanted signals include:

- Ferrite beads

- Line inductors

- Common mode chokes

- X and Y capacitors

- TVS (trans-voltage-suppression) diodes

- Varistors

- Shielding

Ferrite beads absorb signals over specific frequency ranges and dissipate the energy as heat. Inductors and capacitors are used together to divert currents to ground. They act as frequency sensitive voltage dividers and therefore must be carefully selected based on material characteristics, the frequencies involved, and circuit impedances.

Transient suppression with TVS diodes requires a careful match between speed, power capability. And parasitics such as capacitance to provide the proper protection without affecting performance. Ethernet and USB data lines are a good example. Shielding can effectively limit radiated noise when properly applied and is available in many forms including cans, tape, magnetic film, and gaskets.

Figure 4. Common components used to mitigate EMI

Online tools like Würth Elektronik’s REDEXPERT Filter Design tool help select the right components by calculating and plotting the expected response based on real component characteristics and parasitics. Other tools help find and select the many individual components. Other resources, such as application notes and webinars, can provide more details on choosing the right components for specific use cases. These tools along with early consideration of EMC can help ensure your project’s success.

To keep learning about EMC, stay tuned for next month’s article explaining how to calculate and manage EMC losses.

Leave a Reply